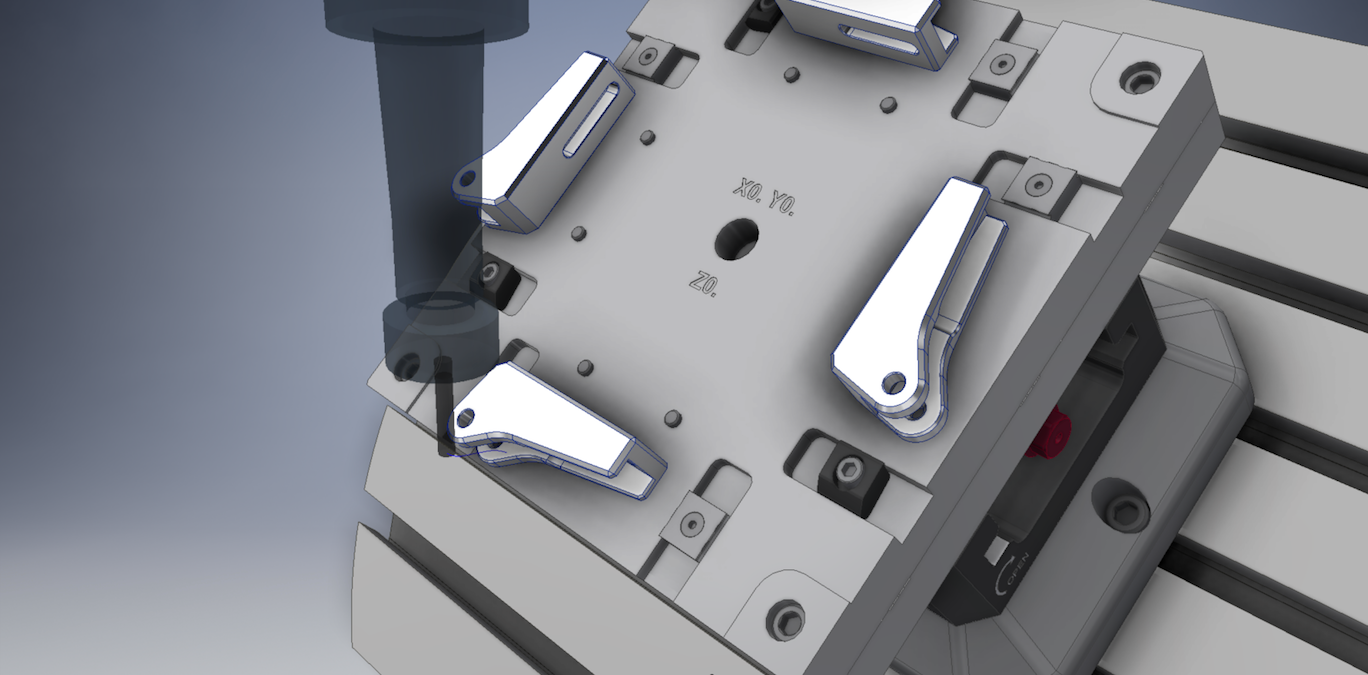

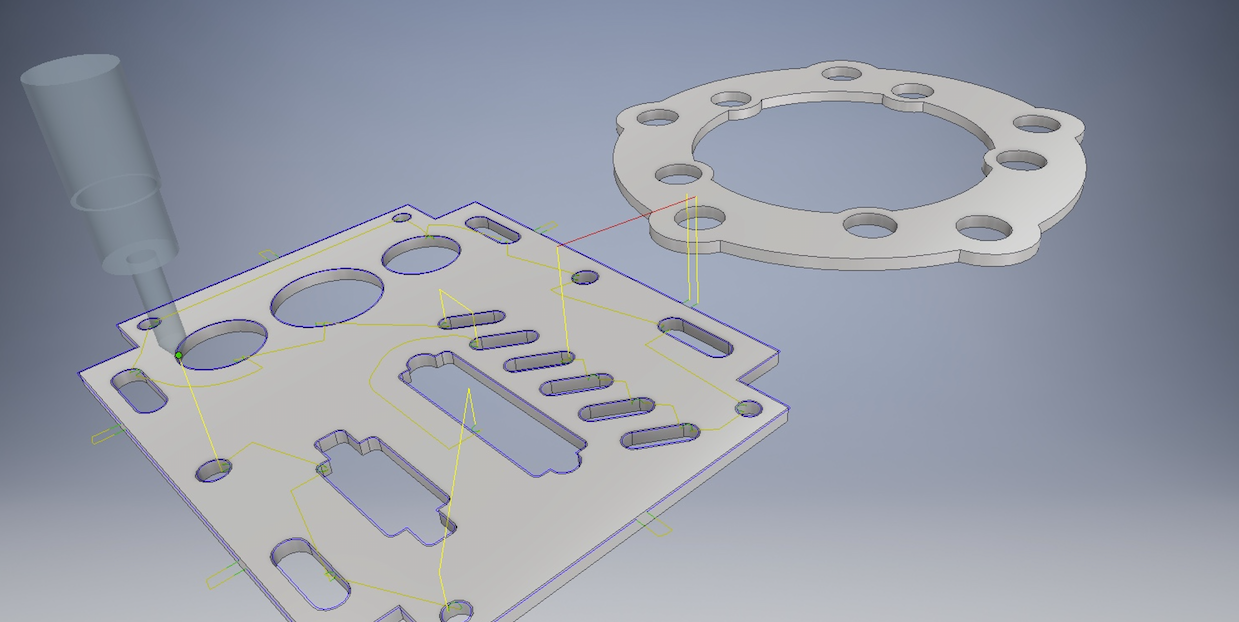

Create complex 3D geometry for multi-axis, high-speed CNC machining

PowerShape® manufacturing CAD software combines surface, solid, and mesh modeling to help engineers prepare molds, dies, and other complex parts for additive, subtractive, or hybrid manufacture.

Boost CAM programming with flexible modeling tools.

Create geometry to better control CAM software such as PowerMill and FeatureCAM.

- Work with any combination of surface, solid, or mesh data.

- Import, analyze, and repair third-party designs.

- Fix faults that can complicate downstream processes.

Work faster with focused modeling for manufacture tools

Access wizards to automate common modeling tasks. Quickly convert product designs into molds, tools, and dies ready for CNC machining,

- Core and cavity splitting

- Electrode design and manufacture

- Automated rib capping for EDM

Compare Support Plans

Best for Teams Needing Foundational Support

$195

per year/per user

What's Included

Support Portal Access

Learning Management System Access (Lite Version)

Ideal for Companies Needing Real-Time, High-Priority Assistance

$595

per year/per user

What's Included

Direct Phone & Live Support

Learning Management System Access+

Minor Post Processor Updates

Quarterly Live Classes

Best Practices Sessions

15% Discount on NexGen Services

Comprehensive, Tailored Services for Large and Complex Operations

Contact for Pricing

Everything in Platinum, plus...

Bank of Tailored Training Hours

Dedicated Direct Phone & Live Support

Customized LMS Access & Content

"What's New" Webinars

Quarterly Business Reviews

See what's included in our support plans and get started today!

Autodesk PowerShape Training Classes

Essentials/Intermediate

Autodesk PowerShape Essentials/Intermediate

Description: This is a comprehensive class covering a wide range of capabilities provided by PowerShape. Key topics include wireframe modelling, surface modelling, solid modelling, direct editing, solid repair, and modelling for manufacture. Electrode and reverse engineering training are delivered in a separate class.

Type: Web/Remote

Pre-Requisites: None

Course Length: 4 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Electrode

Autodesk PowerShape Electrode

Description: Creating and pulling electrodes along with workflow and design toolsets specifically for electrode manufacturing. Depending on customer specific workflow, separate training on PowerMill electrode might be required.

Type: Web/Remote

Pre-Requisites: None

Course Length: 2 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Custom Training

Autodesk PowerShape Custom Training

Description: Custom training is developed together; taking into account specific needs of the students, type of machines, and assortment of typical parts being produced. Customer will need to provide sample parts and current process workflow in advance, which will be leveraged in the training curriculum that will be modified to specific needs.

Type: Web or Onsite

Pre-Requisites:

- 2+ years of use with the software or;

- Completion of a qualified Essential training course or;

- NexGen Solutions Consultation

Course Length: TDB

Training Videos

Getting Started with PowerShape

This course explores the essential skills of PowerShape for new users.