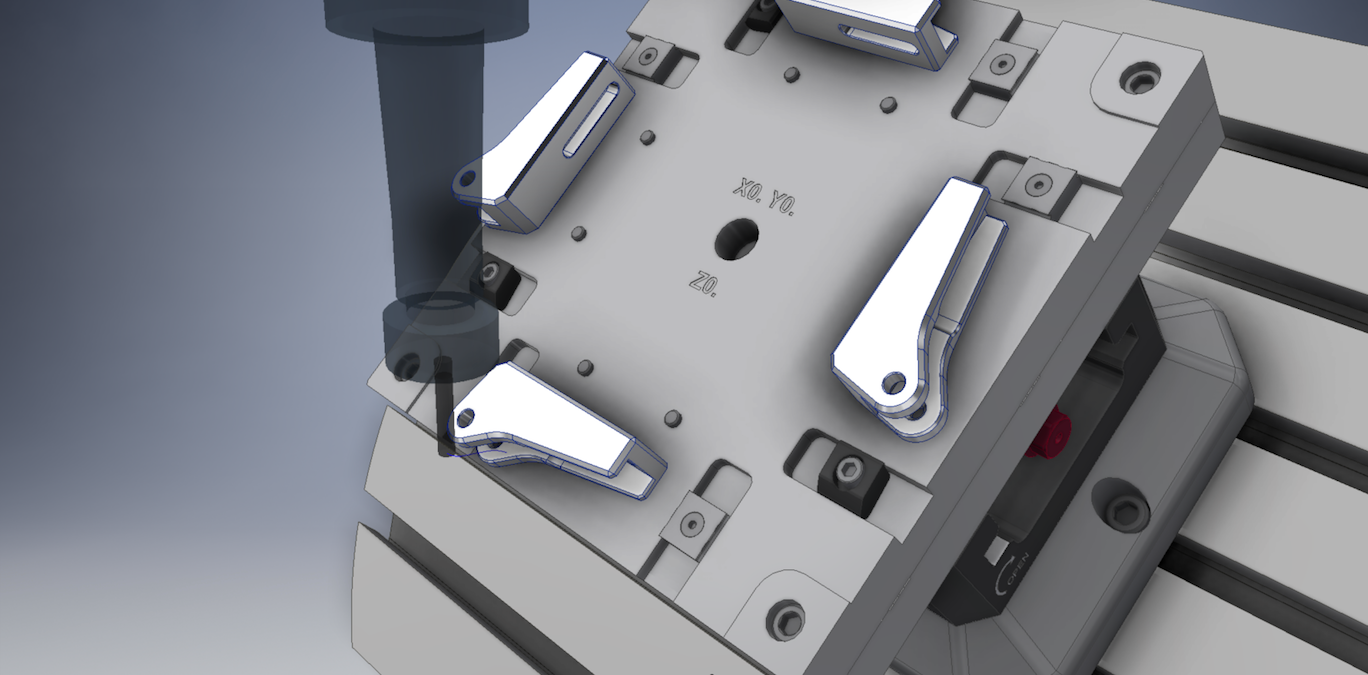

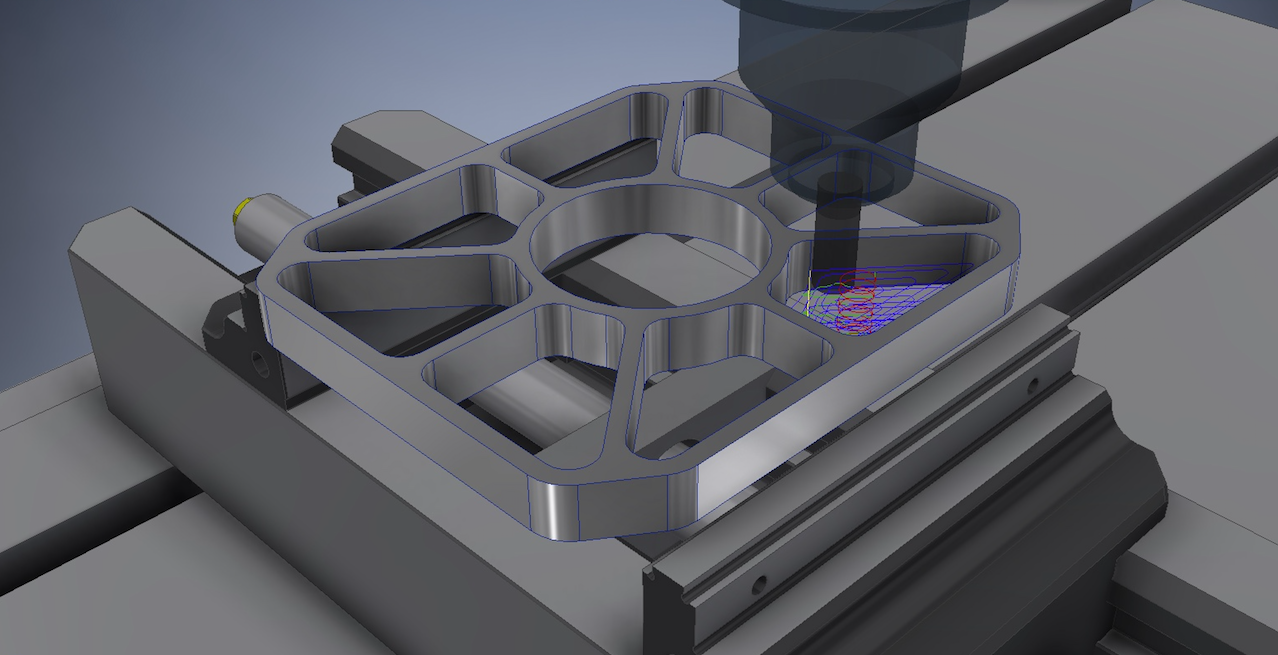

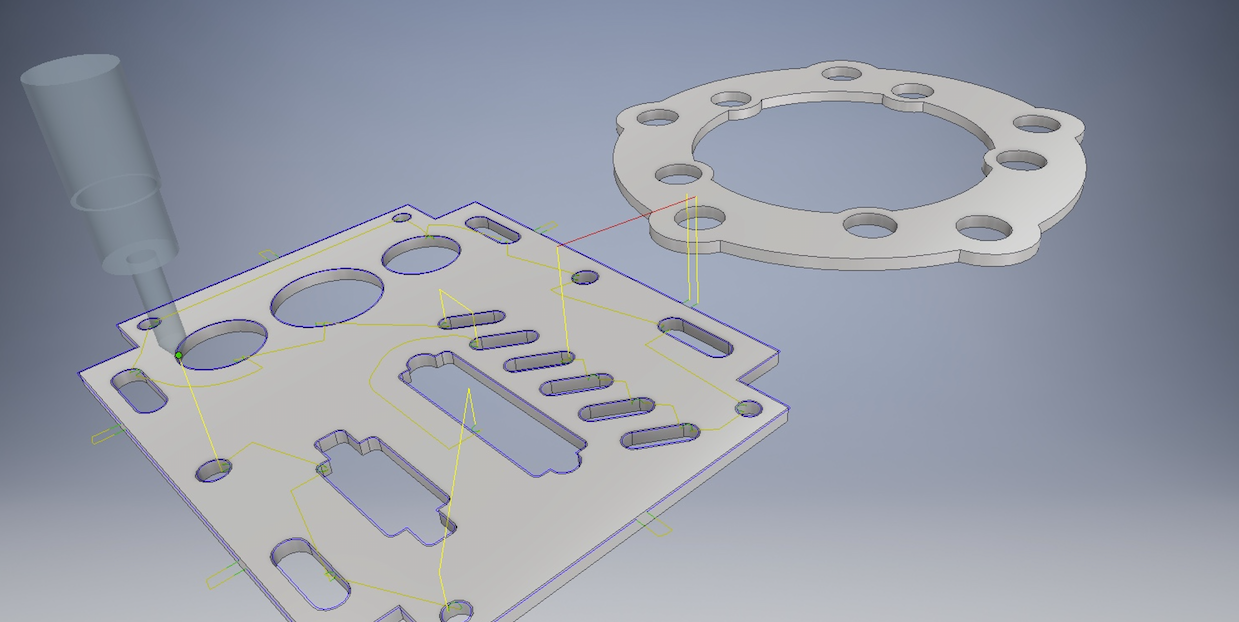

Move from CAD design to machined-quality parts faster

FeatureCAM® CNC programming software automates your workflow from design to NC code. Reduce programming time and increase consistency for a range of CNC applications.

This comprehensive solution gives you access to FeatureCAM Ultimate, PartMaker, Fusion 360, Fusion Team, and HSMWorks.

Standardize practices and promote repeatability

- FeatureCAM CNC programming software uses manufacturing knowledge to intelligently make decisions, produce results, and remove repetitive processes

- Manufacturers can standardize best practices and quality standards, and promote repeatability between all employees using the same setup

FeatureCAM gives you comprehensive machine support

- Use a single interface for all your CNC applications

- Get more from your 3-axis to 5-axis mills, lathes, turn-mill centers, Swiss lathes, and wire EDMs

- Use simulation tools to visualize programming within your machining envelope

Compare Support Plans

Best for Teams Needing Foundational Support

$195

per year/per user

What's Included

Support Portal Access

Learning Management System Access (Lite Version)

Ideal for Companies Needing Real-Time, High-Priority Assistance

$595

per year/per user

What's Included

Direct Phone & Live Support

Learning Management System Access+

Minor Post Processor Updates

Quarterly Live Classes

Best Practices Sessions

15% Discount on NexGen Services

Comprehensive, Tailored Services for Large and Complex Operations

Contact for Pricing

Everything in Platinum, plus...

Bank of Tailored Training Hours

Dedicated Direct Phone & Live Support

Customized LMS Access & Content

"What's New" Webinars

Quarterly Business Reviews

See what's included in our support plans and get started today!

Autodesk FeatureCAM Training Classes

Essentials

Autodesk FeatureCAM Essentials/Intermediate

Description: The main objective of this class is to teach you the workflow of programming parts as well as use of automation techniques for FeatureCAM. Program a variety of milling and turning parts, ranging from simple 2D wireframe to more complex models incorporating organic surfaces as well as traditional 2.5D features.

Type: Web/Remote

Pre-Requisites: None

Course Length: 3 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

3D Surface Milling

Autodesk FeatureCAM 3D Surface Milling

Description: Learn the workflows and best practices for 3D Surface milling, toolpaths, and application on models. Includes advanced topics such as stock models, boundaries, leads and links.

Type: Web/Remote

Pre-Requisites: Essentials/Intermediate

Course Length: 2 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Advanced Turn-Mill

Autodesk FeatureCAM Advanced Turn-Mill

Description: This class starts with an in-depth foundational understanding of turning toolpaths and strategies. Then learn how to utilize multiple turret turn-mill machines with synchronization, learning the configuration and workflows necessary to get repeatable results.

Type: Web/Remote

Pre-Requisites: Essentials/Intermediate

Course Length: 2 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Wire EDM Essentials

Autodesk FeatureCAM Wire EDM Essentials

Description: Wire Essentials training covers 2 through 4-axis wire.

Type: Web/Remote

Pre-Requisites: None

Course Length: TBD

Custom Training

Autodesk FeatureCAM Custom Training

Description: Custom training is developed together; taking into account specific needs of the students, type of CNC machines, and assortment of typical parts being produced. Leverages the training curriculum, modified to specific needs.

Type: Web or Onsite

Pre-Requisites:

- 2+ years of use with the software or;

- Completion of a qualified Essential training course or;

- NexGen Solutions Consultation

Course Length: TDB

Training Calendar

- SU

- MO

- TU

- WE

- TH

- FR

- SA

- 29

- 30

- 1

- 2

- 3

- 4

FeatureCAM Best Practices: Web

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 1

FeatureCAM Best Practices: Web

- 2

Training Videos

For trialists and new users, this module will cover the essential skills of programming a wide variety of parts in FeatureCAM.