We all know how critical electrode design, manufacturing, and machining are in making sure your facility can remain competitive, cutting-edge and attractive to customers. Autodesk’s possesses a large amount of tools to help facilitate all of your needs in this dynamic market. Autodesk PowerShape will allow you to create, edit, and optimize electrode geometry in ways that other platforms simply cannot. The user will have access to proprietary tools and templates that are built into the software to make the struggle of electrode design a thing of the past. Once the user has easily navigated the design side of electrode creation, Autodesk’s PowerMill, and it’s built-in electrode plug-in, takes over and makes manufacturing electrodes as simple as a few clicks.

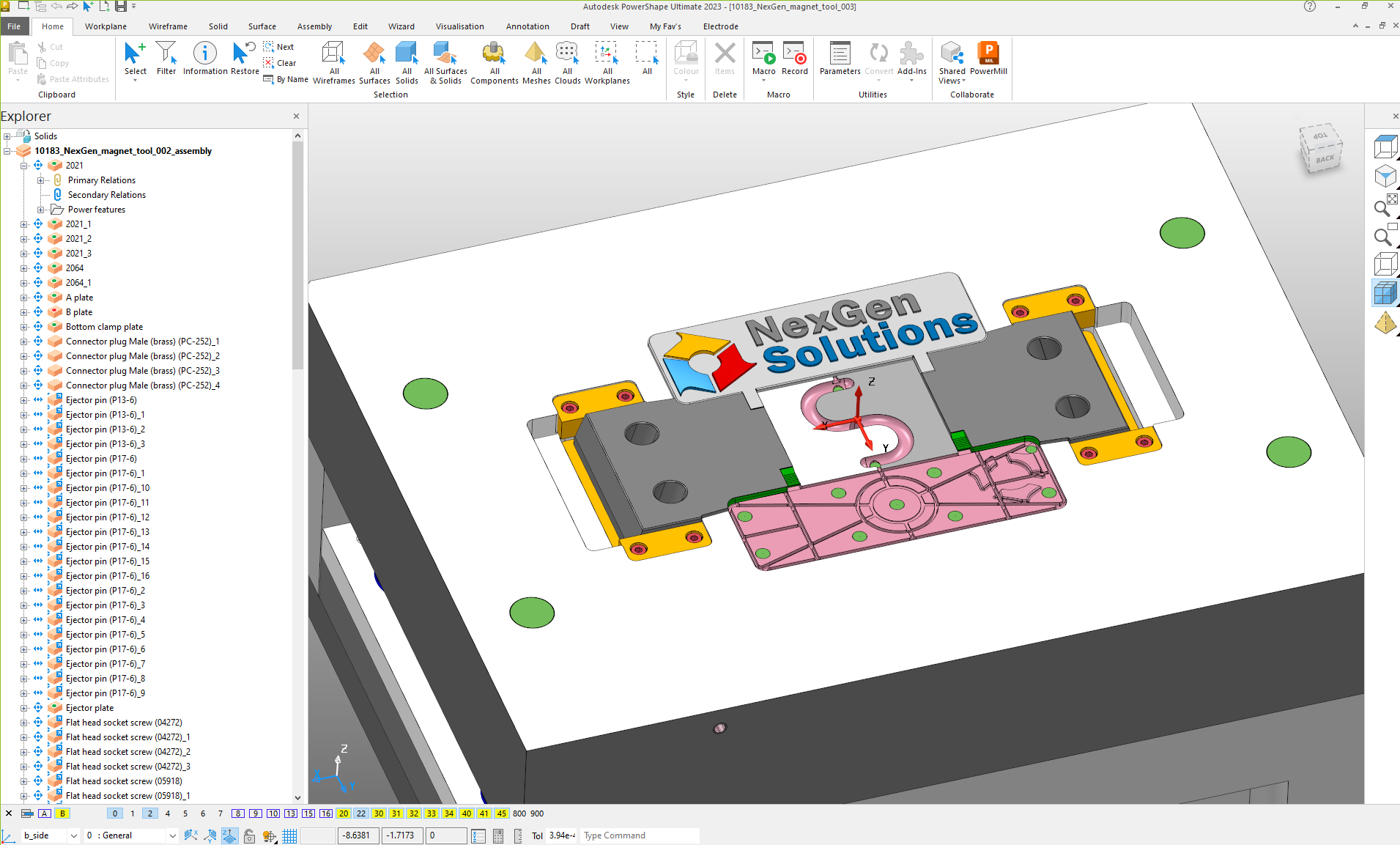

Autodesk’s PowerShape stands out as the premier solution for electrode design, offering streamlined and robust features throughout the entire process. One feature that stands out more than any other is the Electrode Wizard, a tool designed to simplify the extraction of electrodes into 3D models. Whether you’re working with complex geometries or intricate molds, PowerShape’s Electrode Wizard efficiently identifies and extracts electrode shapes with remarkable accuracy and consistency.

The wizard guides the user step-by-step, allowing for precise customization of parameters such as electrode size, position, and orientation. Moreover, PowerShape’s intuitive interface ensures that even novice users can swiftly grasp the intricacies of electrode design, reducing design iterations and minimizing errors along the way.

Once electrodes are designed and extracted from PowerShape, the next step is to generate toolpaths for CNC machining. This is where Autodesk PowerMill comes into play, offering advanced capabilities to automate and optimize toolpath generation. The integration between PowerShape and PowerMill facilitates a seamless transition, allowing users to effortlessly import electrode designs for further processing.

PowerMill’s Electrode Wizard takes automation to the next level by automatically calculating the most efficient toolpaths for electrode machining. By analyzing factors such as material properties, cutter specifications, and machining constraints, the wizard generates optimized toolpaths tailored to each electrode’s geometry. This not only saves significant time but also ensures consistent machining quality across the board.

By harnessing the combined power of Autodesk PowerShape and PowerMill, manufacturers can significantly enhance their electrode design and CNC programming workflows. The seamless integration between these two software solutions enables a streamlined approach from design to machining, minimizing manual intervention and maximizing efficiency. Furthermore, the advanced capabilities offered by PowerShape’s Electrode Wizard and PowerMill’s Electrode Wizard empower users to achieve unparalleled levels of precision and accuracy in their machining operations. Whether tackling simple or complex projects, manufacturers can rely on these tools to deliver optimal results while reducing costs and lead times.