In the ever-evolving manufacturing environment, precision and efficiency are crucial. Mold making, a key industry of CNC machining, demands innovative solutions for intricate shapes and exact dimensions. Fusion, equipped with a versatile toolkit, is at the leading edge of mold making. It offers strategies to streamline processes and raise quality standards. Check out these 3D Toolpaths to increase your mold making production using Fusion.

- Steep and Shallow

- Geodesic

- Corner

- Surface Inspect

Steep and Shallow: Simplifying Machining with Compound Strategies

Steep and Shallow in Fusion combine various machining methods to deliver an all-in-one toolpath for multiple part surfaces. It enhances surface finish and speeds up machining for steep and shallow areas on 3D models. One advantage is the Spiral option, smoothing transitions in shallow areas and eliminating marks. Additionally, the Smooth Offsets feature removes sharp corners, enhancing surface quality and speeding up machining. The toolpath also includes a centerline trace called Remove Cusps at Junctions to improve surface quality by removing cusps at the center of the toolpath. Though this toolpath is only available with the Manufacturing Extension, the added automation quickly pays for itself within days.

Geodesic: Precision Finishing for Complex Surfaces

Geodesic milling is an ideal toolpath for finishing complex surfaces and handling undercuts. Geodesic works by planning multiple passes with different offsets across a parts surface, creating a flawless toolpath and exceptional surface finishes. Geodesic’s flexibility in setting machining boundaries and handling multi-axis operations highlights its capabilities. With options to choose drive surfaces, machining boundaries, and a selection of Blend or Scallop toolpath strategies (with the option of Remove Cusps at Junctions), it offers a complete solution for almost all mold making applications.

Corner: Navigating Small Spaces

The Corner toolpath in Fusion is tailored for machining small areas like, you guessed it, corners, where there is leftover material from previous operations. By picking a reference tool larger than the selected tool for the operation, the toolpath checks remaining stock and identifies the unreachable areas from previous tools. Compared to the Pencil toolpath, the Corner toolpath offers precise machining control using the Reference Tool geometry.

Surface Inspection: Quality at Every Step

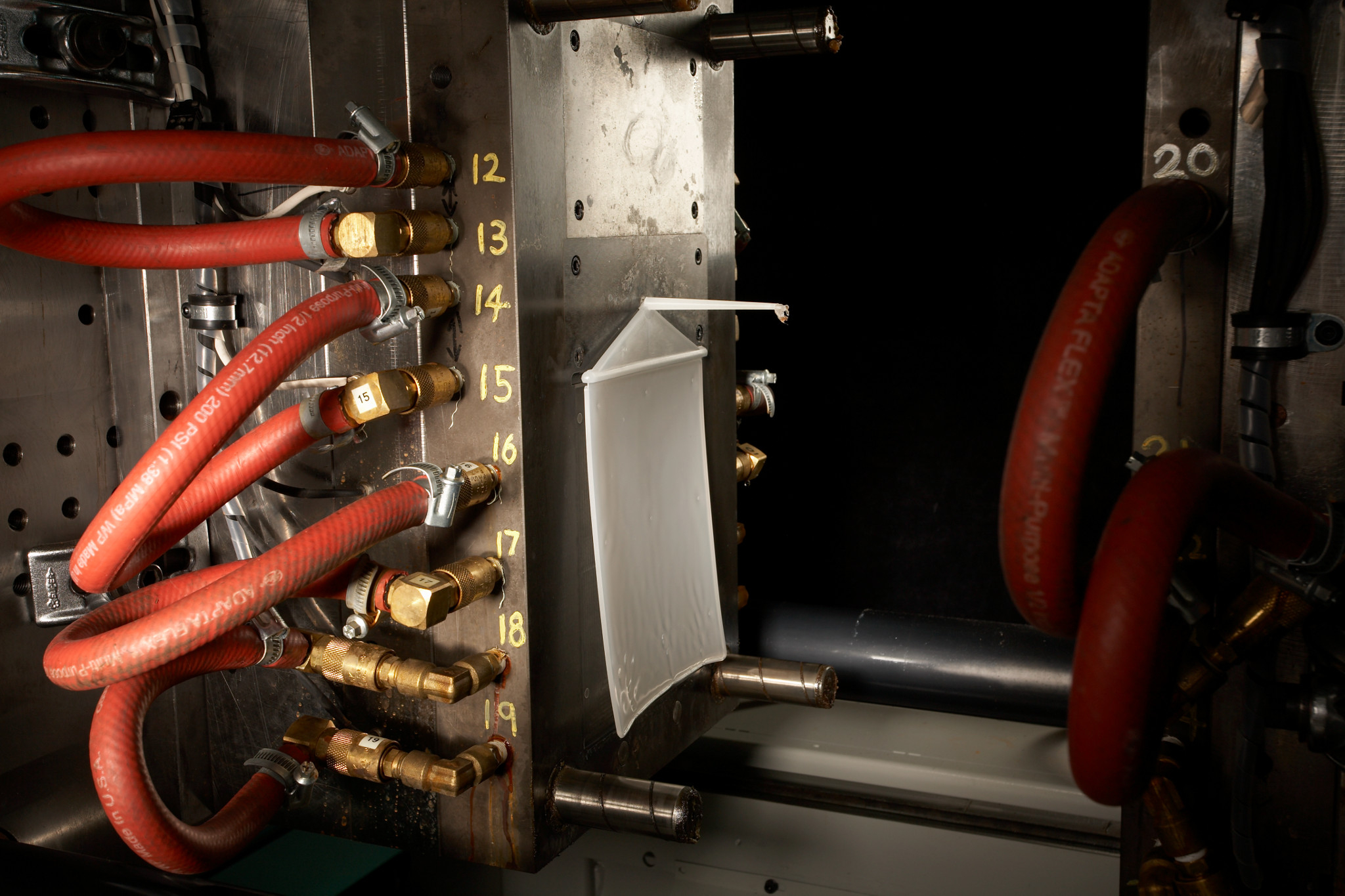

Surface Inspection is vital in Fusion's mold making tools, emphasizing the importance quality at the source. It enables real-time comparison of measured points with CAD model positions, using the machines spindle probe. This proactive approach reduces errors, lowers scrap rates, and ensures tight tolerances are met, resulting in improved production efficiency and higher quality products.

Embracing the Future of Mold Making with Fusion

In manufacturing, having CAD/CAM software that is devoted to keeping up with technology is essential for staying competitive and maximizing efficiency. Fusion leads the way in mold making, offering advanced solutions to improve processes and quality. With tools like Steep and Shallow, Geodesic milling, Corner machining, and Surface Inspection, Fusion enables manufacturers to excel. Embrace Fusion for limitless possibilities.

Want to Learn More About Fusion?

Click the Button to Contact Us and a NexGenSolutions' rep will reach out!