Build in manufacturability from day one.

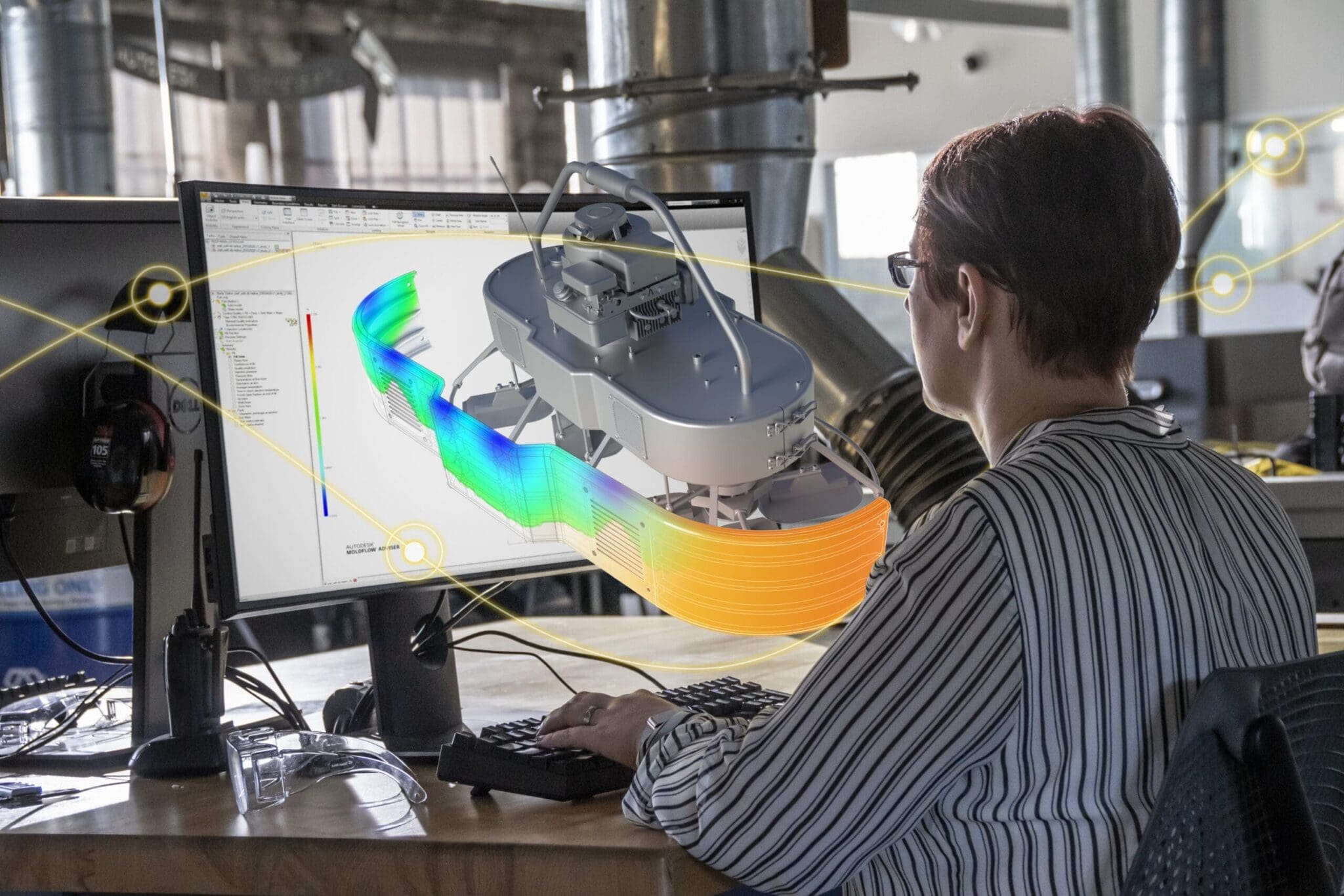

Mold simulation gives part designers the ability to explore more design options more rapidly and identify manufacturing issues before final part geometry is locked in.

Lower Part Cost

Ongoing Optimize cycle time, gate location, wall thickness, and

other variables.Faster Time to Market

Minimize iterations caused by warpage and shrinkage, and reduce

tooling time.Higher Product Quality

Address weld lines, air traps, and other issues when it is less

expensive to make changes.

Autodesk Moldflow is an industry-leading solution for optimizing plastic part designs before manufacturing. Use it to find the ideal balance of cycle time, cost, and part quality for your products.

Achieve success with

Plastic flow

Simulate the flow of thermosets and thermoplastics to help optimize plastic part and injection mold designs, reduce potential part defects, and improve the molding process.

Tooling layout

Evaluate and optimize cavity location, hot and cold runner systems, and gating configurations.

Mold cooling configuration

Improve cooling system efficiency, minimize part warpage, achieve smooth surfaces, and reduce cycle times.

Shrinkage and warpage

Evaluate plastic parts and injection mold designs to help control shrinkage and warpage.

Material library

Robust library with over 11,500 grades of material from a variety of suppliers to effectively evaluate various material options for your part design.