Why PartMaker?

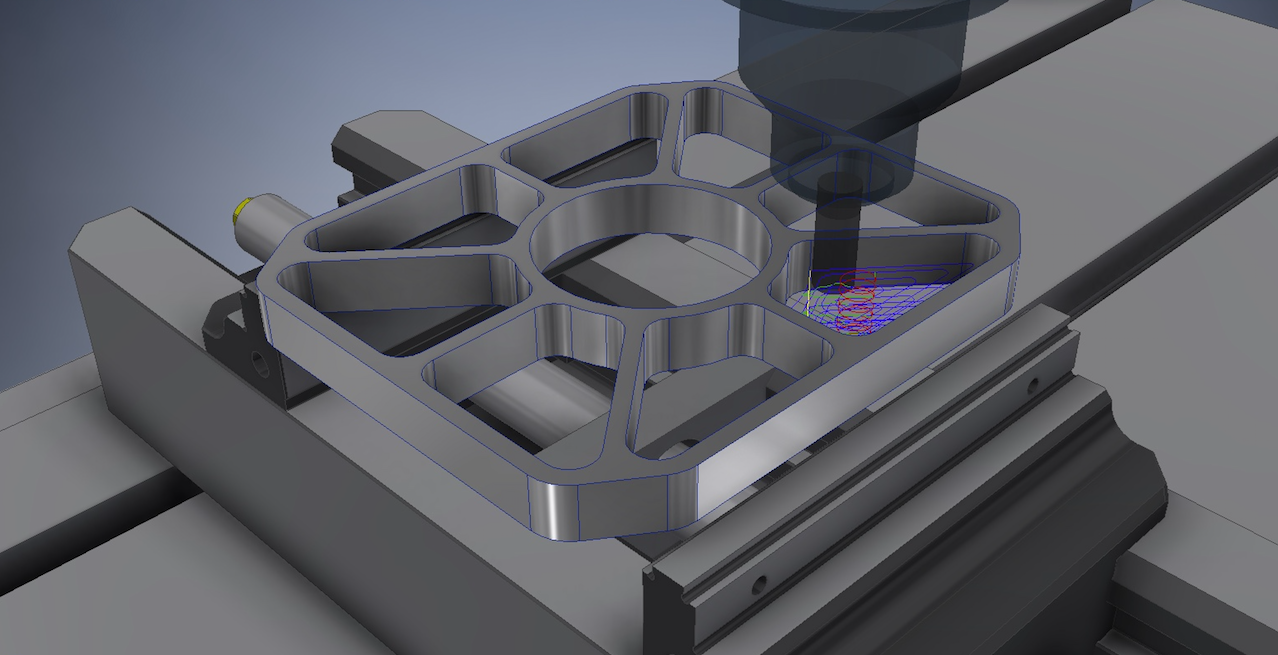

PartMaker was developed for Swiss lathes and supports the techniques commonly used by Swiss programmers.

- Precision programming gives you fine control over your machine and provides clarity during the programming of turning with live tooling.

- Swiss specific functionality gives you several options to manufacture your parts based on your available tooling and batch size.

- Quick process synchronization automatically inserts wait and queue codes into your NC programs for an efficient cycle time, with minimal effort.

Expert Knowledge

NexGenCAM has strong in-house knowledge of programming and implementing software for Swiss lathes through established relationships with many machine tool manufacturers. This helps to ensure our post-processors generate accurate NC code for your machines. Due to this focus, many leading users of Swiss-type lathes have chosen to standardize with PartMaker.

Greater Flexibility

PartMaker is available as part of FeatureCAM® Ultimate, bringing together technology to deliver our highest level of capabilities for production machining. This single package includes:

- PartMaker software for high precision programming for Swiss-type lathes.

- FeatureCAM software for automated CNC programming.

FeatureCAM Ultimate gives you access to the best of both. You can choose between using either PartMaker, FeatureCAM or a combination of the two to suit your needs and preferences.

Compare Support Plans

Best for Teams Needing Foundational Support

$195

per year/per user

What's Included

Support Portal Access

Learning Management System Access (Lite Version)

Ideal for Companies Needing Real-Time, High-Priority Assistance

$595

per year/per user

What's Included

Direct Phone & Live Support

Learning Management System Access+

Minor Post Processor Updates

Quarterly Live Classes

Best Practices Sessions

15% Discount on NexGen Services

Comprehensive, Tailored Services for Large and Complex Operations

Contact for Pricing

Everything in Platinum, plus...

Bank of Tailored Training Hours

Dedicated Direct Phone & Live Support

Customized LMS Access & Content

"What's New" Webinars

Quarterly Business Reviews

See what's included in our support plans and get started today!

Autodesk PartMaker Training Classes

Essentials/Intermediate

Autodesk PartMaker Essentials/Intermediate

Description: Essentials covers an intro to knowledge-based Swiss Style and Turn/Mill programming and an overview of the best workflows to programming effectively - import, extraction, simulation, milling, along with basic and advanced strategies. This includes setup, tool libraries, cycles libraries, and the use of the process table to order, edit and synchronize toolpaths between the main and sub spindles. At the end of the course is a 1 day lab, where each student will apply the skills to their parts to demonstrate proficiency.

Type: Web/Remote

Pre-Requisites: None

Course Length: 3 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Advanced Machining

Autodesk PartMaker Advanced Machining

Description: This 3D Advanced Machining class includes 3D roughing and finishing techniques. Roughing techniques include model area clearance with the model and vortex machining. Finishing strategies include raster, 3D offset, rest machining, pencil trace, and corner finishing. 5-axis positioning with 3+2 tool tilt and 5-axis simultaneous swarfing is also taught as a part of this class. At the end of the course is a 1 day lab, where each student will apply the skills to their parts to demonstrate proficiency.

Type: Web/Remote

Pre-Requisites: Essentials/Intermediate

Course Length: 2 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Turn-Mill

Autodesk PartMaker Turn-Mill

Description: This two-day course covers Turn/Mill programming and an overview of the best workflows to programming effectively - import, extraction, simulation, milling, along with basic and advanced strategies. This includes setup, tool libraries, cycles libraries, and the use of the process table to order, edit and synchronize toolpaths between the main and sub spindles. Day two will focus on milling with the B-Axis. If additional help is needed with 3D machining, this would have to be scheduled as a custom 3rd day.

Type: Web/Remote

Pre-Requisites: Essentials/Intermediate

Course Length: 2 days*

*Day is defined as 6 hours of training, however class length varies based on student progress.

Custom Training

Autodesk PartMaker Custom Training

Description: Custom training is developed together; taking into account specific needs of the students, type of CNC machines, and assortment of typical parts being produced. Leverages the training curriculum, modified to specific needs.

Type: Web or Onsite

Pre-Requisites:

- 2+ years of use with the software or;

- Completion of a qualified Essential training course or;

- NexGen Solutions Consultation

Course Length: TDB

Training Calendar

- SU

- MO

- TU

- WE

- TH

- FR

- SA

- 28

- 29

- 30

- 31

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

PartMaker Essentials Training: Web

- 14

PartMaker Essentials Training: Web

- 15

PartMaker Essentials Training: Web

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

Training Videos

Getting Started with PartMaker

In this course, you will learn the fundamentals of PartMaker SwissCAM.