The Advancement of Prototyping

The practice of prototyping has been a staple in any engineering and manufacturing practice since the dawn of mass scale production. The process of idea, design iterations, pre-production, and final mass production is a cycle that needs to be carefully managed and controlled to avoid catastrophic supply, finance, and other economic pitfalls.

Each stage of the cycle has evolved in numerous ways over the years, but the prototyping or “design iteration” phase has seen the most advancement. Through leaps in technological advancements like generative design, FEA (Finite Element Analysis), and additive manufacturing, prototyping has been labeled a new name: rapid prototyping. Autodesk’s Fusion enables users from any industry to access these powerful new technologies, and to create cutting edge products while reducing lead time on their production. all while being effortless to use and cost effective to your business. Let's take a look at these three technologies and the value they provide.

Unleashing Generative Design

Generative Design is the ultimate tool to create design iterations based on a product’s base functionality, its objective constraints, and visual appeal. It starts with defining your design’s parameters such as material, weight, manufacturing methods, and more. Fusion’s advanced calculation algorithm processes the information provided to generate a quick and diverse set of iterations of the design. Each solution provides a unique characteristic for the design: optimize certain aspects of the design’s functionality, reduce manufacturing time, reduce weight, increase yield strength in susceptible shear or break locations, and so much more. This process can help designers and engineers develop innovative solutions in a matter of hours, not months compared to the more traditional manual methodologies.

Ensuring Integrity with Finite Element Analysis

Finite Element Analysis (FEA) lets designers evaluate their designs under real world conditions. Users can conduct studies like stress, thermal, vibrations and more to the design to verify itssafe operating and integrity. The process begins by defining the parameters and constraints, much like the gen design workflow. For example, for thermal studies, you can assign thermal load points, direct cooling airflows, and even control ambient temperatures. By using pre-manufacturing verification workflows, organizations can save valuable time and money to confidently design products and limit or altogether eliminate potential mechanical failures of these products. Autodesk Fusion gains its FEA technology from Autodesk's other industry leading meshing and simulation technologies and large material databases like Autodesk CFD and Moldflow, which on their own have provided trusted and accurate results for decades.

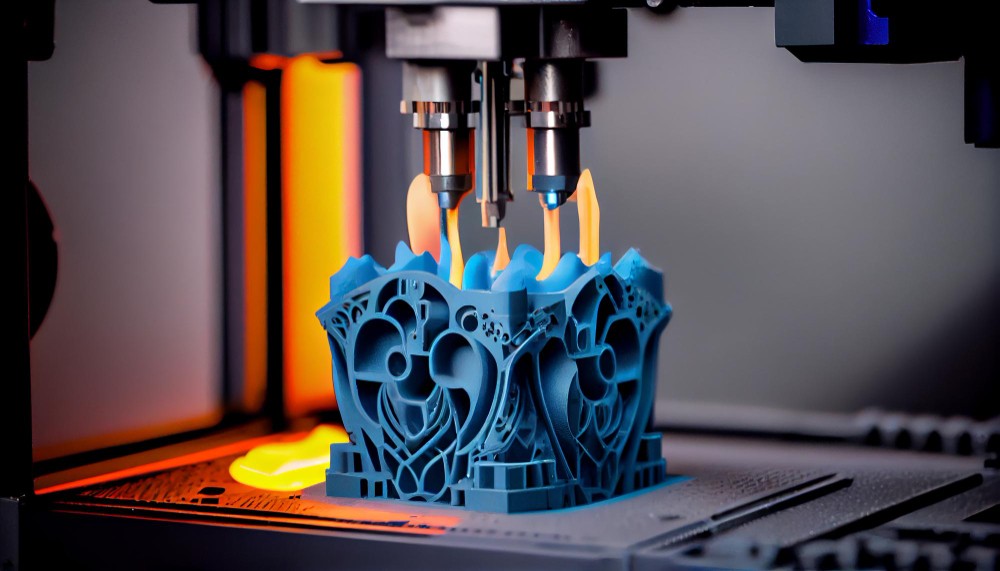

The 3D Printing Revolution

Finally, the third and arguably the most important technology for rapid prototyping is Additive Manufacturing, more commonly known as 3D printing. This revolutionary technology has pushed the boundaries of what is regarded as “possible” as a manufacturable product. 3D printing can create physical prototypes quickly and efficiently, being low cost and highly sustainable. Without the need for an expensive mold design, tooling or subtractive machining for a small batch prototyping process, product designers can reduce the prototyping time and move to market in a much shorter time. There is a wide variety of 3D printing processes; filament based, laser based, deposition, and polymerization to name a few. Printers can be found in all different types of sizes and capable of printing in multitudes of different materials thereby letting product designers create prototypes that resemble the end products material. Autodesk Fusion has the ability to create a toolpath for these printers to print out prototype models, and even fine tune specific properties of the printer to print at different styles.

Elevate Your Prototyping to the Next Level with Autodesk Fusion

Autodesk Fusion is changing the game in prototyping, making it faster, more intuitive, and frankly, more fun. It's the tool that brings together design, simulation, and 3D printing into one seamless process, helping you turn your ideas into reality without the usual fuss.

Interested in seeing how? Join us for an eye-opening webinar. Umair Riyas, our go-to expert on Fusion, will take you through its coolest features, from generative design to the magic of moving from concept to 3D print with ease. It's scheduled for February 29 at 1 p.m. ET, and it's your chance to get up close with what Fusion can do.

Looking to get more out of Fusion? Whether you're starting fresh, seeking some expert advice, or ready to jump into more advanced use, we're here to help. Talk to us, take part in a Fusion Accelerator training, or simply start by getting your hands on Fusion through our e-store.

Let's not just talk about innovation—let's make it happen. Sign up for the webinar and discover the difference Autodesk Fusion can make in your projects. Let's unleash your creativity together. See you at the webinar!

- Need Tailored Advice? Connect with one of our experts today. Discuss your specific needs, challenges, and ambitions to see how Fusion can transform your product development process.

- Looking to Master Fusion? Sign up for a Fusion Accelerator training class. Our comprehensive, hands-on courses are designed to enhance your skills, ensuring you get the most out of this powerful software.

- Ready to Start? Purchase Autodesk Fusion directly from our e-store and begin your journey to faster, more efficient, and innovative product development.

Act Now: Don't let the potential of your ideas fade. Talk to an expert, enroll in a training class, or buy Fusion now to unlock your creative and operational potential. Your path to mastering Fusion starts here. nexgensolutions.com/contact

Ready to See Fusion In Action?

See the value of Fusion for prototyping, the ultimate all-in-one CAD/CAM software. Join us February 29 @ 1 p.m. ET to see our live Fusion demo. Register now!