Check out our certified customer reviews for projects completed!

Customer Success Stories

Autodesk Moldflow | Partnership you can count on

Customer Challenge 3-Dimensional Services Group provides rapid manufacturing services that allow us to engineer and build functional prototype parts as well as low-to-medium volume production parts up to 70% faster than industry standards. Moldflow provides us with precise calculations to reduce prototype mold costs, avoids rework, and ensures final product quality. NexGenCAM has partnered with…

Meyer Tool & Mfg. – Video on our Youtube

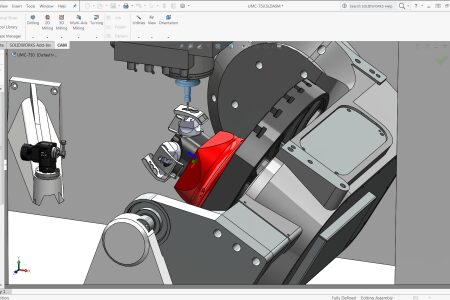

Follow along as Meyer Tool & Mfg. takes you through how Autodesk products have been implemented in all aspects of their manufacturing process. Starting with Inventor to get your design off paper into CAD to using Fusion 360 with Powermill to transform that CAD into finished goods to meet customer demands and needs….

Custom Fusion 360 Post with Rapid Support

Customer Challenge Steel Craft Technologies, an ISO 9001-2015 certified steel service center located in Grand Rapids, Michigan, continues to raise industry standards for quality steel products along with on-time delivery. Steel Craft Technologies strives for excellence daily by consistently producing quality steel products that always include best-in-class customer service. Steel Craft’s continued focus on quality…

Adding Value In Quoting Jobs With Autodesk FeatureCAM That Used To Be Out Of Reach

Customer Challenge Stark Industrial Inc. is a 3-generation family business started in 1959 as a distributor of cutting tools and industrial supplies. Over time, we transitioned from a distributor to a manufacturer of precision metal parts and assemblies for a variety of industries. We’re also one of the most successful distributors of complex dimensional precision…

Vault Made our Data Management Simple

Customer Challenge AMPG is a High Mix Low Volume Make-to-Stock manufacturer with over 50,000 unique products. Our company was started in New York in 1987 as a distributor with manufacturing capabilities coming online in 2002. We manufacture a wide range of products including configurable components, fasteners, machine tool accessories, architectural products, and measuring tool accessories….

FeatureCAM Improved Programming Speed by 40%

Customer Challenge Chips MFG is part of the dental division at Steris Corporation. Our company specializes in manufacturing dental and medical components. We have been using Autodesk PartMaker for over 13 years and we are very satisfied with it, but over the years our parts portfolio changed. We started to produce bigger and more complex…

Autodesk CAM Solutions Deliver Quality, Efficiency, and Capability

Customer Challenge Early experience with Pratt & Whitney on the joint strike fighter program gave me a real-world appreciation for sub-tenths precision and high-end manufacturing processes. While a design and engineering manager for a high-end architectural sign company, some community college machine shop training gave me a start in hands-on machining. This culminated in an…

Zero Defects by Using Moldflow

Customer Challenge For 60 years, OTTO Engineering has been designing and manufacturing a full line of control switches and for over 25 years, audio accessories for unique and demanding applications. Located in Carpentersville, Illinois, we are recognized worldwide for superior performance and innovative products. OTTO Engineering is a vertically integrated manufacturer with in-house injection molding,…

Custom Fusion 360 Post Delivered in Under 24 Hours

Customer Challenge Angel City Woodshop was born in early 2016, founded by Paul Moorhead. Paul was a self-taught furniture maker and operated alone for some time. Over the years we have expanded into a team and have built a reputation in Los Angeles as one of the premier high-end custom furniture shops in the city….

Easy-To-Use Autodesk FeatureCAM Drastically Increases Productivity

Customer Challenge Sinicon Plastics was founded by a man named Tony Sinico. A child of the Great Depression and first generation Italian-American. In 1989, our current owner, David Allen, purchased Sinicon from Tony and his son. When David bought the company there were seven employees and eight machines located in an old, 5,000 sq ft…

Retaining Profits with PartMaker

Customer Challenge We here at Metalogic are Industry-leaders in power generation manufacturing. We leverage our highly skilled team and necessary software systems to machine, fabricate, and engineer quality products for a wide range of industries. These include power generation as well as medical, aerospace, automotive, semiconductor, industrial, and consumer industries. We first turned to Autodesk’s…

With Autodesk FeatureCAM, Our Production Time Increased by 30%

Customer Challenge Founded in the early 80’s, Jakes Inc. specialized in machine rebuilding and die making. Our company quickly branched out to full-scale machining and fabrication, specializing in medium to large fabrications up to 25 tons. We are still family owned and operated and the quality of our machined and fabricated products is our highest…

Comprehensive Programming Solution Delivers Results

Customer Challenge Cast Aluminum Solutions develops and manufactures industrial components, the majority of which have heating or cooling capabilities, for the global aerospace, microelectronics, medical, food service, and industrial fluid markets. CAS products are a critical element of the production process of electronic devices we use every day, the medical equipment that keeps us healthy,…

Reducing Programming Times by 90%

Customer Challenge Norstar was founded in London, the UK by Chris Bonehill in 1998, initially as a ship brokerage company specializing in Sale and Purchase and new building. In 2001, the office relocated to Monaco to focus on ship owning, investments, and management. Norstar is able to deliver safe, efficient, and reliable transportation and logistics…

Vault Drastically Decreased our Miscommunication Errors

Customer Challenge At Imperial Industries, we’ve been designing and manufacturing specialized storage solutions for more than 41 years – constantly evolving to meet the changing needs of your industry. That dedication to growing alongside our valued customers has allowed us to advance from a maker of agricultural feed bins into the industry leader in manufacturing…

Complex Manufacturing at a Higher Efficiency Rate with Autodesk FeatureCAM

Customer Challenge Designcraft Manufacturing is a leader in CNC volume milling and turning for the Aerospace, Defense, and Medical industries. We specialize in producing precision products for our customers which include parts with extremely complex geometries and contouring. With over 40 years of operation under our belt, we realize the essential need for Autodesk FeatureCAM…

Improving CNC Programming Results

Customer Challenge Flotec, incorporated in 1983, creates respiratory products that enable providers to save lives. Since the beginning, the core activity has been manufacturing for the medical, industrial, and Original Equipment Manufacturing markets. The products include specialized regulators, pressure reducers, flow control valves, liquid oxygen valves, fill to vent valves, quick disconnect fittings, relief valves,…

Rapidly Increase R&D and Production

Customer Challenge In business since 1994, Aimpro Tactical grew up with traditional CAD/CAM processes and machining techniques. In 2018, the team developed a new product, now covered by 2 US Patents, from which they built a prototype and completed small batches on a Prototrac DPM. Using a separate third party vendor to draw/model in Solidworks…

Bringing Capabilities In House To Streamline Processes

Customer Challenge Elliott Guitars is a small boutique guitar shop that has been in business for over 16 years. We cater to musicians who expect more from the quality of their guitars than the average player. As builders and musicians ourselves, we are constantly looking for ways to improve our designs and components to build…

Vault for CAM and NC Data

Customer Challenge Pyromation began operations in 1962 and has become one of the leading temperature sensor manufacturers in North America. The ISO 9001-registered firm and Lean Manufacturing Enterprise custom designs and builds thermocouples, RTDs/PT100s, thermowells and sensor assemblies to customer specifications for multiple applications around the world. Too often we see Customers whose engineering and…